OKI Circuit Technology has declare New printed circuit board (PCB) design improves component heat dissipation by up to 55 times. The Japanese company has more than 50 years of experience developing and manufacturing PCBs, and its product portfolio covers a wide range of applications. This particular innovation, with stepped round or rectangular copper coins mounted on a PCB, targets even best air cooler are impractical – like tiny devices or outer space applications.

Heat dissipation is one of the issues that engineers involved in high-power electronics often have to overcome. One of the most common ways to solve the problem of component overheating on a PCB is to add a heat sink or even actively Install fan. However, something like a fan isn’t always practical. In space, no one can hear your CPU screaming, and since there’s no air, it won’t be cooled by fans.

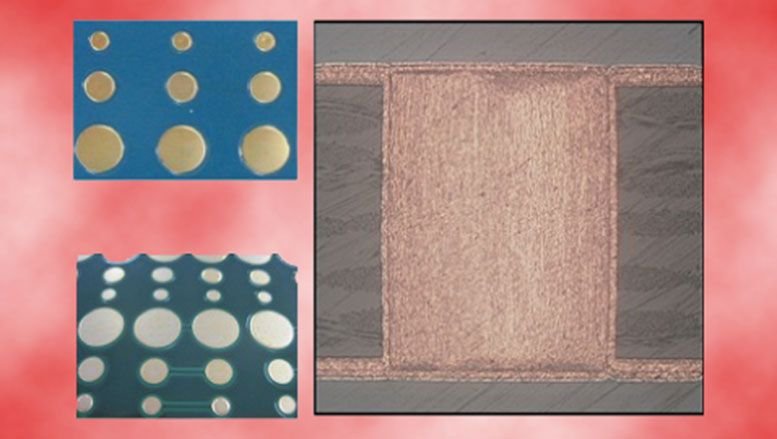

If you look at OKI’s high current/high heat radiant panels product page You’ll see that it already has PCB solutions using embedded copper coins, thick copper foil routing, and metal core routing. It now refines copper coins by using stepped coin thicknesses and choosing round or rectangular coins based on your design preference.

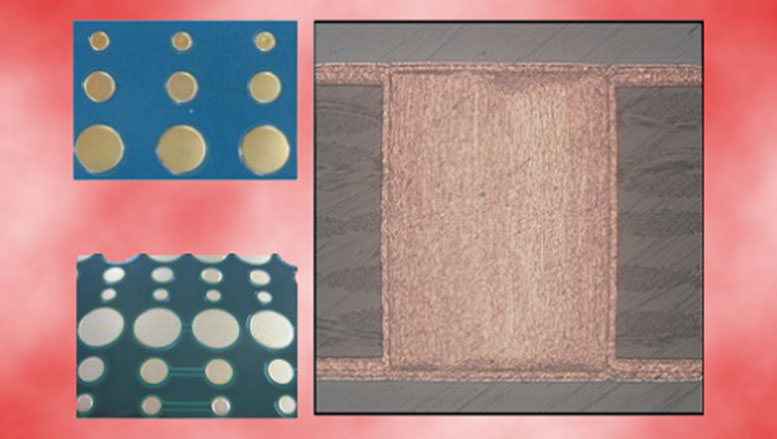

By “coin,” OKI refers to a rivet-like copper structure. Also, if it says stepped, it means that one end of the coin or rivet is a different size than the other. Taking the ladder coin as an example, the diameter of the joint surface with the electronic component is 7mm, and the diameter of the heat dissipation surface is 10mm.

“The newly developed stepped copper coins have a larger heat dissipation area relative to the bonding surface with the heat-generating electronic components to improve heat conduction efficiency,” OKI explains. It then goes on to explain how its new rectangular coins are ideally suited to the transition from traditional rectangular coins to Heat is absorbed from heating electronic components.

OKI’s PR suggests that this PCB technology may be best suited for micro and space applications, and in the latter case it’s said to improve heat dissipation by up to 55 times. However, we immediately wondered if it could benefit PC components and systems,

Component manufacturers such as ASUS, ASRock, Gigabyte, and MSI often brag about their extensive use of copper in motherboards and other components. Maybe OKI’s new copper ladder coins will also be beneficial. OKI says the coins extend through the PCB, conducting heat to the large metal casing. They may be connected to backplanes and other cooling devices.