- Castrol plans to launch fluids-as-a-service model to eliminate waste and improve sustainability

- Immersion cooling has become an important part of the race to achieve AGI

- As integrated smart city data centers become mainstream, Castrol hopes to play a key role in immersion cooling

CC Wakefield & Co. Limited was established in 1899 and initially focused on the production of train and heavy machinery lubricants. Over time, the company expanded its expertise and developed specialized lubricants for automotive and aircraft engines, incorporating castor oil (a vegetable oil extracted from the castor bean) to ensure performance in extreme temperature conditions. lower performance. The product was called Castrol, and the company later changed its name to Castrol after its famous creation.

125 years later, Castrol Always at the forefront of innovation, it applies its extensive expertise in fluid engineering to address modern challenges.

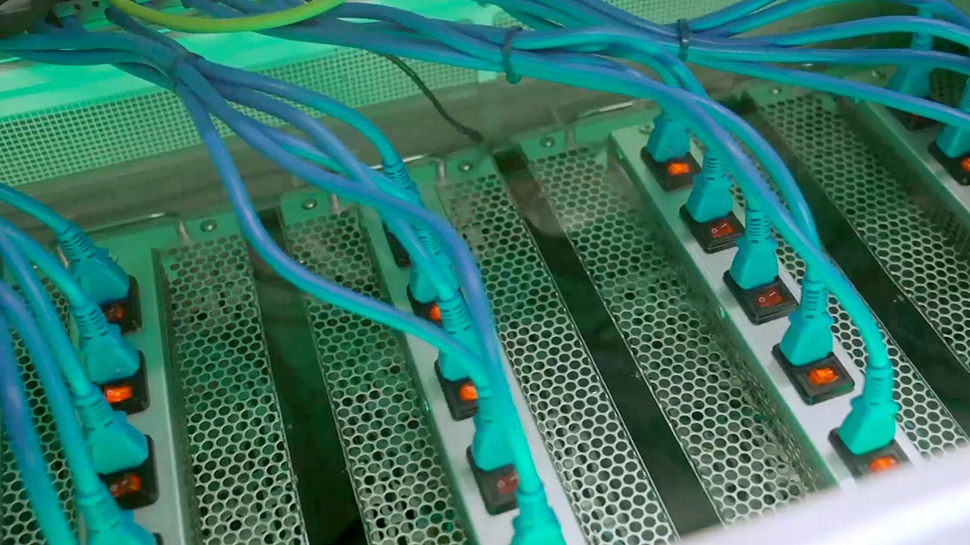

One of its key focus areas is the development of advanced dielectric fluids for use in immersion cooling systems. This method immerses the entire servo in a non-conductive liquid, absorbing heat and transferring it away from the components, eliminating the need for traditional fans.

Advanced thermal management

The Castrol ON Liquid Cooling Center of Excellence in Pangbourne, UK, is a state-of-the-art R&D center for liquid cooling technology.

The facility develops custom solutions and rigorously tests fluid dynamics, material compatibility and server performance to address the challenges of traditional cooling methods.

On a recent visit, save review Had the opportunity to see Castrol cutting-edge immersion tanks from suppliers such as GRC and Submer and was impressed by the adaptability and efficiency of the solution.

Writer Jordan Ranous notes: “In one of the test units, we observed GRC’s storage tanks, which glowed a striking green color due to the specific liquid used by Castrol. The servos immersed in the tanks were undergoing compatibility testing. Performance and performance testing. Castrol ensures that every component from the CPU to the cables can operate efficiently in an immersion cooling environment without performance degradation.

Castrol ON range of single-phase dielectric fluids (including DC15 and DC20) are designed to provide advanced thermal management, durability and safety while maintaining efficient performance at operating temperatures of 40°C to 50°C, which some systems can Processes up to 70°C.

Chris Lockett, vice president of electrification and product innovation for Castrol parent company BP, said save review“, “Currently, about 40% of the power consumption in data centers is used for cooling. Immersion cooling can reduce that number to less than 5%, significantly reducing electricity and water usage.

Data center energy consumption is estimated to account for 2-3% of global energy consumption, and current liquid cooling efforts are primarily focused on direct-to-wafer solutions. Immersion cooling has the potential to set new standards for thermal management, and Castrol hopes to lead this transformation, positioning itself as a “one-stop partner for liquid cooling solutions today and into the future.”