Inside Honda’s Solid-State Battery Breakthrough

Electric cars, of course, are the future of the automotive industry, since the brands, in fact, began their march in relation to carbon neutrality. Nevertheless, anxiety in the range and slow charging are obstacles to an average person passing to an electric car. However, solid -state batteries (SSB) can be a solution.

In the race for the production of functioning solid -state batteries, Honda recently made several huge breakthroughs that could put them in front of the package. While other brands may have gained an advantage, the Japanese automaker proved why they are a leader in this industry.

Studying innovative Honda production methods and the opening of a new object, we will study how the automaker can soon be ahead of some direct competition. There, innovative methods can pave the path to electric cars with solid state batteries on our roads long before the end of the decade.

To give you the most relevant and accurate information used to compile this article, were obtained from various websites of manufacturers and other authoritative sources, including TopSpeed.

Connected

Not ready for a complete electric car? Check these 10 long hybrids

PHEV is a good step for drivers who want to gradually move to a complete electric car, while it is possible to use gas if necessary.

The new Honda demonstration line will prepare them for mass production

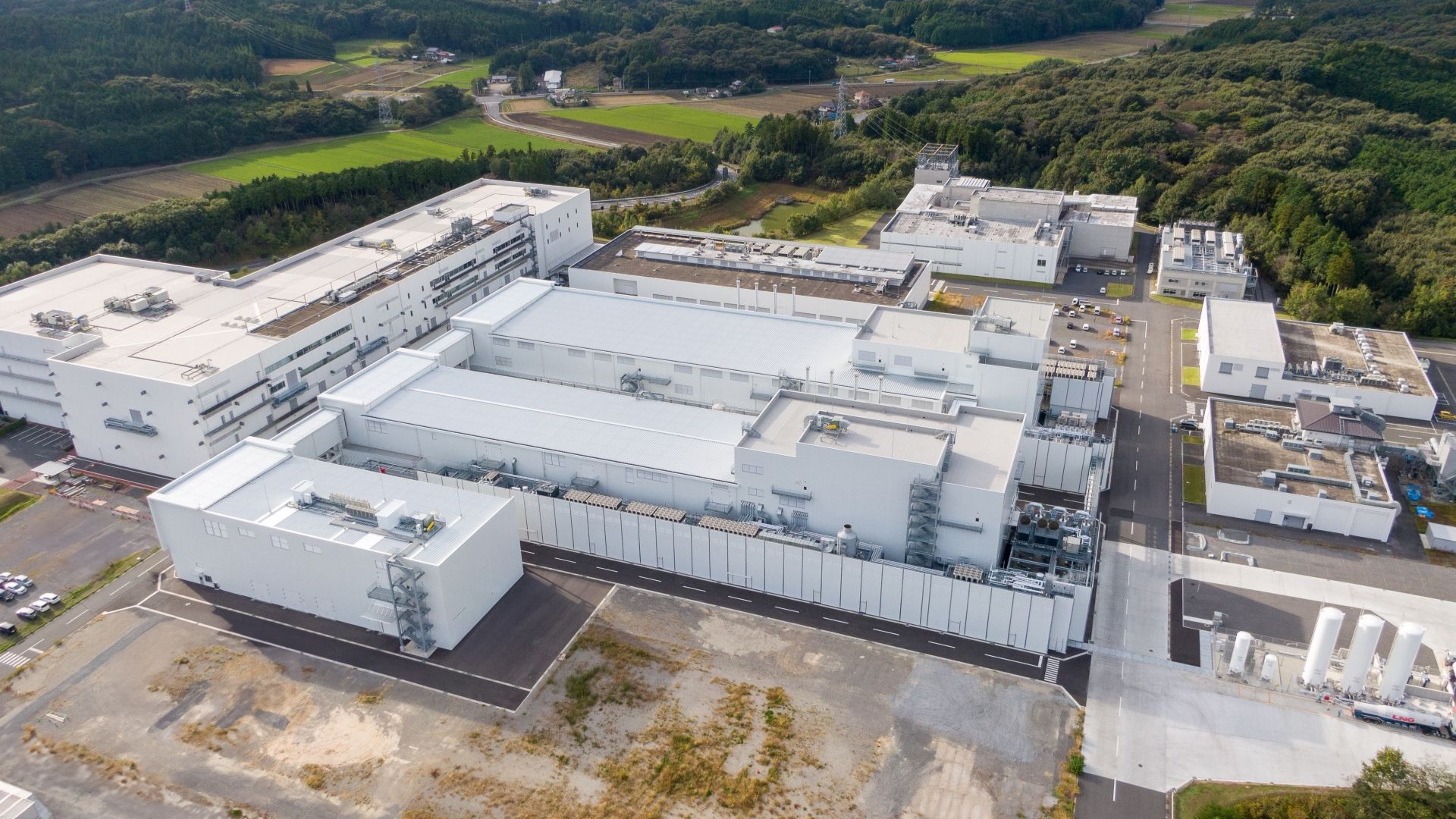

Ariel Image of the Demonstration line of the solid battery of Honda ‘

Some other players may have beaten Honda to the punch when it comes to solid state batteries, but the Japanese automaker, of course, took the initiative with his last step. The brand has created a functioning demonstration that demonstrates how a full -fledged production line can build solid -state batteries.

-

A production line is a demonstration of a smaller scale. Honda still completes production methods for large -scale work

-

The line is aimed at optimizing production and reducing costs

-

Production was supposed to start in January 2025

Demonstration line

At the end of last year, Honda announced that they opened a demonstration production line that can be used to produce solid -state batteries. This line is located in the field of Honda research and development in Sakura -City Japan, occupying about 300,000 square feet of the object.

Cells produced by this line are their own Honda design. This is that the car manufacturer for a long amount of time invests a lot of time and money. For purposes with a firm state, electric vehicles were spoke for decades, but it took billions of dollars and a lot of time to bring them closer to production.

How is it transferred to mass production

Despite the fact that there were several car manufacturers who have issued statements about how they are preparing to produce solid -state batteries for their electric vehicles, Honda is the only one with evidence of the concept. This demonstration line shows how close to full -scale production are.

The Honda announcement also came with an exciting date. According to the previous announcement, they would have already begun production on these solid -state batteries, as they had to start in January of this year. Mass production was the biggest problem for solving SSB, and Honda seems to be the only company that produces them now.

Connected

Home EV Home Wardpoint charger will not make you find your own electrician

Without friction, the experience of charging Home EV.

Honda – Pioneer in Battery Innovation

Honda was invariably one of the world leaders when it comes to innovation in the world of engines and power units. That is why it makes great sense that their breakthroughs in the segment of electric vehicles are so revolutionary. The processes that they use bring us closer to functional solid -state batteries in electric cars.

Rolon’s key is the key

One of the keys to how Honda received where they are today is the development of the rolling technique. Using this technique, batteries, in other words, a stamp using a large press. This increases energy efficiency by increasing the density of layers of solid electrolytes.

Where normal batteries use paste or liquid to store their energy, while batteries with a solid state store their power in solid form, usually powder. The problem is that this leaves tiny gaps of air, which is obviously not suitable for electrical conductivity, as this causes bending. The batteries are together, this air literally accelerates, which means that the continuous electrolyte of the batteries is installed by an almost perfect contact with the electrode.

Avoiding cunning dendrites

Those who followed the development of evolution in the technology of a continuous battery will no doubt hear about dendrites. In fact, since lithium is separated from other connections inside the battery, it is formed in small crystals that grow over time, destroying the battery from the inside. They were a huge problem when it comes to the durability of batteries.

Honda came to her solution for this problem. They developed a plastic polymer layer, which will act as a barrier, preventing the touches of lithium inside the battery. Although it sounds like an excessively simple solution, it can add years to the service life of the battery.

Connected

GM and Arrangpoint build “hundreds” more chargers EV

Thanks to the new strategic partnership.

Scaling production for use almost everywhere

Front 3/4 shots of the 250th delivery Hondajet

Honda began its beginning in the world as a manufacturer of cycling engines. Since then, they often joked that they are a motor company that also produces cars. This, of course, is true today, when the company is developing a wide range of engines intended for numerous applications. With the transition to electricity, it makes sense that they will provide their future as a transmission giant.

Earth, sea and air

As part of the press release of the Japanese brand announcing the opening of its demonstration line, the company also shared details about its plans for the implementation of a solid-state battery. Honda seeks to integrate this advanced technology into motorcycles, cars and even the planes, signaling the main step forward in electrification in several sectors of transport.

In addition, since Honda produces engines for various mighted ships, it is likely that solid -state batteries can ultimately get into marine applications. This extension will demonstrate the versatility and potential of the Honda breakthrough battery technology even more.

Connected

Nissan and Honda can merge together

The first steps of the merger began.

Solid state batteries are the holy Grail in the world of electric vehicles

Shot from the assembly battery at the Honda factory

There is a reason why Honda spent so much time, effort and money in mass producing solid -state batteries for their vehicles. Tons of automakers around the world were in the same aspiration, considering how they can force the technology to work in an electric car. So what makes them so attractive?

-

Fighting batteries reduce charging time and improve the range by a large number.

-

Tons of companies invested a large amount of time and money in the technology of solid batteries.

-

The cost of production is still high, but Honda seeks to maintain the costs competitive with smart production methods

Advantages of solid -state batteries

One of the biggest reasons why people did not dare to switch to electric cars so that they need a lot of time to charge, and their range, as a rule, is poor compared to gas cars. The range-lane is what is pushing owners of electric vehicles. Enter solid -state batteries.

While each automaker is quoted as a statement that their solid-state batteries will allow various ranges, they are usually at least about 500-mile. Most automakers strive closer to 600 miles up to 900 miles, which is insanely impressive. Fighting batteries can also charge much faster than lithium-ion batteries, which means that they can take only five minutes to fully recharge.

The main disadvantage is that solid -state batteries are still incredibly expensive for production. Some brands even argue that initially their batteries will be used only in luxurious cars.

We still have time to wait

Honda was quoted, saying that they plan to have their hard batteries in vehicles on the “second half of the 2020s.” In fact, this means until 2030. This can still be felt for a long time, but according to the grandiose scheme of things, it is right around the corner. Until then, most electric cars in the market will use more traditional batteries.

Other players in SSBS

Along with Honda there are many other automakers who seek to develop solid -state batteries. In particular, Toyota was a long -standing supporter of technology. They argue that solid state batteries are the key to making EV suitable for mass implementation. While they first demonstrated the prototype back in 2010, production is planned to be launched only in 2026.

There are many other automakers and technological companies that have recognized the need for this technology. From Volkswagen to Renault, solid batteries are considered as the key to power supply in such a way as to make sense for the average consumer. However, with a producer in Honda, they are clear leaders in this race.