Although Samsung OEM is a major contract chip manufacturer, the South Korean government is reportedly considering creating a government-funded contract chip manufacturer, tentatively called Korea Semiconductor Manufacturing Company (KSMC) Korea Business Telecommunications. Industry experts and scholars have proposed this initiative.

Ahn Ki-hyun of the Semiconductor Industry Association called on the government to make long-term investments. Experts predict that investing KRW 20 trillion (USD 13.9 billion) in KSMC could bring economic benefits of KRW 300 trillion (USD 208.7 billion) by 2045. manufacturer. Another concern for publicly held companies like KSMC is whether they will be able to develop advanced manufacturing technologies and secure enough orders from customers to become profitable. It turns out that South Korea needs more fabless software developers in addition to semiconductor manufacturers.

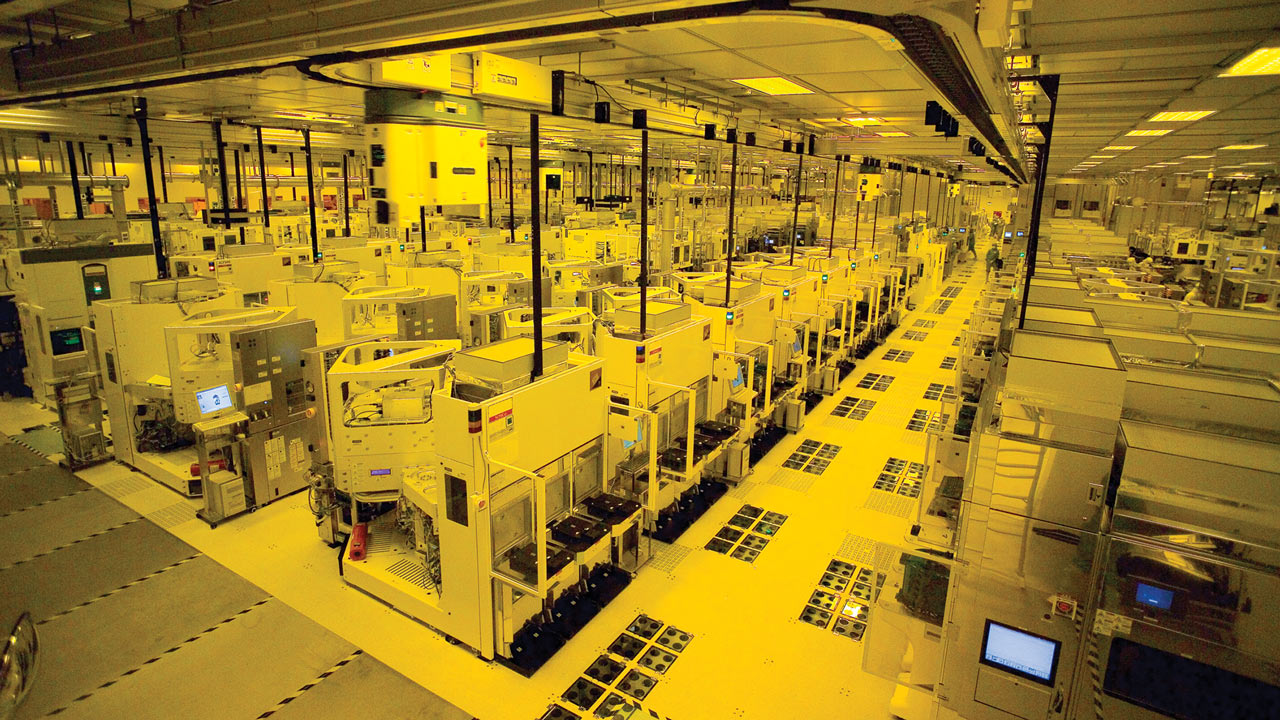

The proposal was presented at a workshop hosted by the National Academy of Engineering of Korea (NAEK). The plan aims to address the industry’s structural weaknesses, such as over-reliance on Samsung’s sub-10nm advanced nodes due to a lack of mature process technology. A lack of manufacturing diversity in South Korea has made it difficult for smaller system semiconductor companies to thrive, as seen in Taiwan, where companies such as UMC and PSMC that focus on mature and specialized nodes complement TSMC’s advanced process technology.

South Korea is the world’s largest memory manufacturer. However, it lags far behind Taiwan in logic process technology and chip design, and the situation is not getting better. According to the report, the main challenges facing South Korea’s semiconductor industry include the widening technology gap with international competitors, insufficient investment attraction, weak growth of fabless companies, talent shortages and restrictive regulations. Experts at the seminar stressed the need to urgently address these issues to maintain South Korea’s global leadership in the semiconductor field.

SK Hynix CEO proposes repurposing Samsung’s old factories with traditional process technology. NAEK calls for increased research and development and financial incentives such as subsidies and tax credits. Other recommendations include easing regulatory burdens, particularly on working hours. TSMC engineers have publicly stated many times that extending working hours can promote the rapid development of advanced process technology.

Not everyone knows that although Chang helped found TSMC, he was invited by Taiwan’s Executive Yuan. The Taiwanese government recognized the potential of the semiconductor industry as early as the 1980s and hoped to establish a semiconductor industry in Taiwan. Although TSMC is not Taiwan’s only semiconductor manufacturer, the flagship foundry is crucial to Taiwan’s semiconductor ecosystem.

NAEK’s initiative draws inspiration from Taiwan’s semiconductor ecosystem, with more than 250 fabless companies thriving in the Hsinchu Science Park alone. By creating KSMC with government support, South Korea can replicate this success and provide small businesses with the resources to grow alongside industry giants like Samsung and SK Hynix. SK Hynix CEO Kwak No-jung proposed direct support for smaller suppliers of materials, parts and equipment, which would benefit large companies as they now have to source many materials from Japan and Taiwan, which means additional costs.

KSMC’s proposal represents South Korea’s ambition to secure its place in the global semiconductor race while addressing fundamental weaknesses in its chip industry. Experts believe that through timely investments and a focus on ecosystem development, South Korea can enhance its competitiveness and generate significant long-term economic benefits.